Optimize the processes in the production of your wood-based materials with smart2i!

Whether flooring, furniture, laminate or engineered wood:

smart2i offers you transparent data for sound production controlling

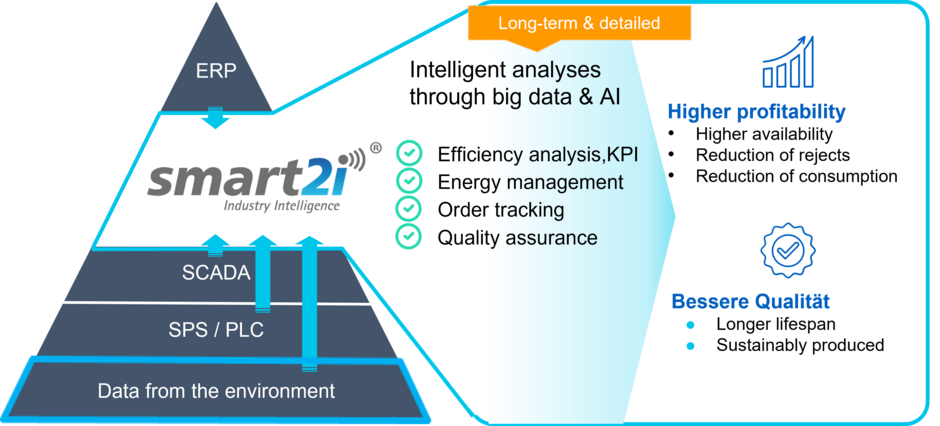

Data is available to you. But you don't have quick access to the data and KPIs that are relevant to efficiently control your production?

smart2i offers you more than just an MES system. smart2i provides you with exactly the information you need about your production at any time and from anywhere. Whether at plant, factory or company level. We are not reinventing the wheel here: with smart2i you can start collecting data if required, but can just as easily integrate data from existing systems into the analysis.

Thanks to this transparency and the intelligent analyses tailored to your needs, you can make quick decisions to optimize your production.

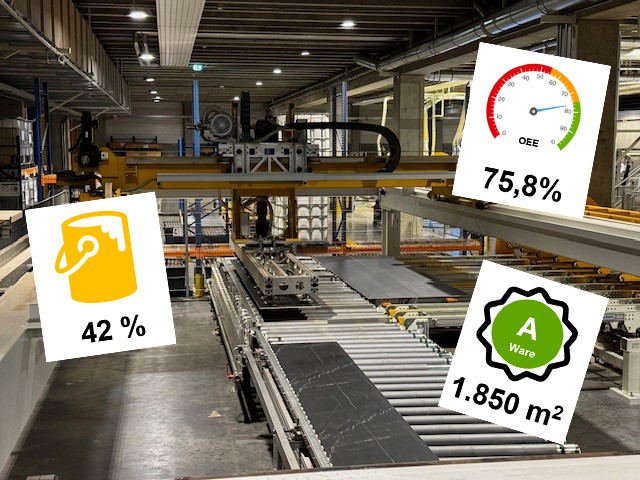

Easy: individual dashboards with smart2i

smart2i conveniently prepares large volumes of data for easy handling: Individually configured dashboards display the data and analyses that are relevant to you. At the touch of a button, you have access to the KPIs you need to take appropriate measures to optimize your production.

Plant operators, plant managers and managing directors can easily access the presentation and analysis they need to make decisions. And if limit values are exceeded, you can be notified so that you can react immediately.

The ease of use is flanked by the ease of implementation: As smart2i is designed as SaaS (Sofware as a Service), you don't need to worry about implementation and connection to existing systems.

We will be happy to show you how to configure the data display and analysis to suit your individual needs using demo dashboards.